The beverage industry is one of the most dynamic sectors of the global economy, encompassing the production of soft drinks, fruit juices, bottled water, beer, and spirits. While the final products bring refreshment to consumers, the manufacturing process is water-intensive and generates high volumes of complex effluent. Effective management of this waste requires a specialized Beverage Wastewater Tank that can handle high organic loads, fluctuating temperatures, and the aggressive chemicals used in sanitization.

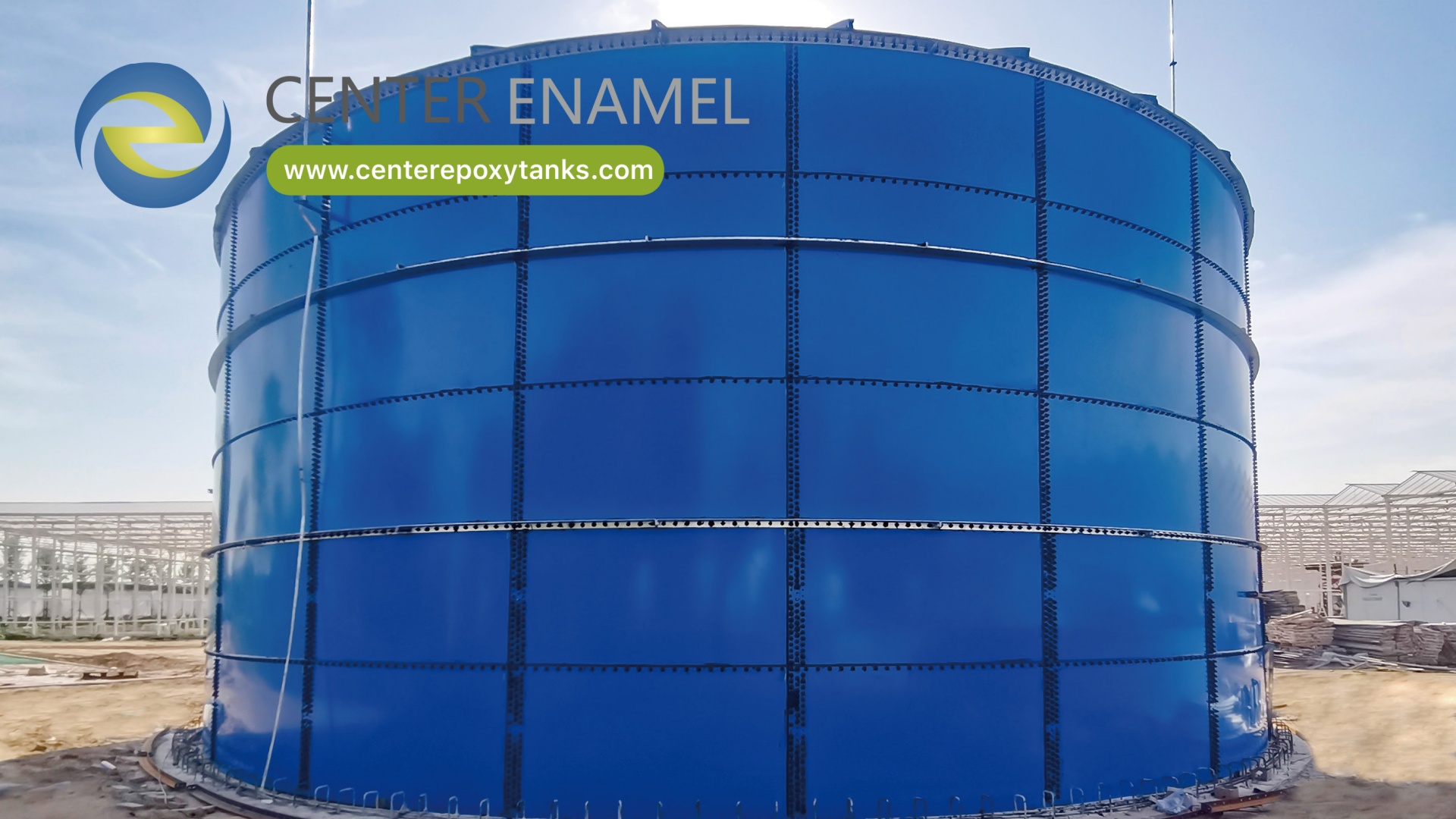

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a leading China Beverage Wastewater Tank manufacturer, provides the sophisticated infrastructure needed to manage these challenging waste streams. By combining our proprietary Epoxy Coated Tanks with high-performance Aluminum Dome Roofs, we offer a durable, low-maintenance containment solution that supports both aerobic and anaerobic treatment processes. With installations in more than 100 countries, Center Enamel is the trusted global partner for beverage producers seeking to achieve environmental compliance and operational efficiency.

Effluent from beverage production is distinct from municipal wastewater due to its high concentration of specific organic and inorganic constituents. A standard Water Tanks solution is often insufficient to meet the long-term demands of a beverage facility.

Beverage wastewater is typically rich in dissolved sugars, flavorings, and alcohol. These compounds contribute to high levels of Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). When stored in a Beverage Wastewater Tank, these organic materials are rapidly consumed by bacteria, a process that can lead to the acidification of the wastewater and the generation of corrosive gases.

Hygiene is paramount in beverage production. Facilities use frequent Clean-in-Place (CIP) cycles involving hot water, caustic soda, and various acidic sanitizers. As a result, the wastewater entering the tank can shift rapidly from high to low pH levels. The Food Processing Wastewater Tank must be finished with a coating that is chemically inert to both acids and alkalis.

Process water from pasteurization, bottle washing, and brewing is often discharged at elevated temperatures. This thermal energy creates constant stress on the tank's structure. Traditional coatings may crack or peel under repeated thermal expansion and contraction, making the choice of a molecularly bonded epoxy finish critical for the tank's longevity.

As a premier China Beverage Wastewater Tank manufacturer, Center Enamel utilizes Fusion Bonded Epoxy (FBE) technology to protect our tanks from the aggressive nature of beverage effluent.

The coating on our Epoxy Coated Tanks is a high-performance polymer that is molecularly bonded to the steel substrate. This process, conducted in a controlled factory environment, ensures a level of protection that field-applied paints cannot match.

Chemical Resistance: The FBE coating is completely inert to the organic acids produced during fermentation and the caustic chemicals used in CIP cycles. This ensures that the structural steel remains isolated from the corrosive liquid.

Smooth, Non-Porous Surface: The glass-like finish of the internal tank wall prevents the buildup of "dead" biomass and scale. This is vital for maintaining the efficiency of mixing and aeration systems within the Beverage Wastewater Tank.

Edge and Bolt Hole Protection: Our automated production process ensures that every panel edge and bolt hole is fully encapsulated in epoxy, eliminating the potential for localized corrosion that often occurs in welded or field-painted tanks.

The headspace of a Beverage Wastewater Tank is the area most susceptible to corrosion. Moisture and corrosive vapors, such as hydrogen sulfide, concentrate under the roof, leading to rapid degradation of traditional steel covers. Center Enamel addresses this by integrating Aluminum Dome Roofs into our designs.

Corrosion Immunity: Aluminum is naturally resistant to the humid and acidic environment found above a wastewater reactor. Our Aluminum Dome Roofs remain maintenance-free for a very long duration, removing the need for periodic sandblasting and repainting.

Biogas and Odor Containment: For anaerobic treatment systems, these domes provide a superior seal for capturing methane-rich biogas, which can be reused as fuel. For aerobic systems located near urban areas, the domes provide excellent odor control.

Thermal Regulation: Maintaining a stable temperature is essential for the health of the microbial cultures used in biological treatment. Aluminum's high thermal reflectivity helps prevent external solar heat from destabilizing the internal process temperature.

Shijiazhuang Zhengzhong Technology Co., Ltd stands as the most professional bolted tank supplier in China. Our status as a leading China Beverage Wastewater Tank manufacturer is built on decades of innovation and global service.

Our Water Tanks are manufactured in accordance with international quality standards, including ISO 28765 and AWWA D103-09. Every panel is subjected to high-voltage spark testing to confirm the continuity of the epoxy coating. This rigorous quality control ensures that our clients receive a product capable of providing maintenance-free service under heavy industrial conditions.

The modular, bolted design of our tanks offers significant advantages for international projects. All components are shipped in standard containers to over 100 countries. Once on-site, the tanks can be assembled quickly using specialized jacking systems, which significantly reduces the construction timeline compared to concrete or welded steel alternatives. This speed is critical for beverage plants needing to expand their capacity without disrupting production.

Center Enamel’s commitment to quality and durability is evidenced by our participation in major wastewater projects across the globe.

Ethiopia Textile Industrial Park Wastewater Treatment Project: This project involved the installation of 20 units of tanks to manage high-load industrial effluent. The successful execution of this large-scale system demonstrates our ability to deliver reliable infrastructure for intensive organic waste treatment in international markets.

Guangxi Qinzhou Chemical Wastewater Project: Handling chemical-rich wastewater requires extreme coating resilience. We provided 11 units of tanks for this project, highlighting the chemical immunity of our Epoxy Coated Tanks in environments with fluctuating pH levels.

Liaoning Petroleum Wastewater Treatment Project: This project required the containment of oily and saline wastewater. Center Enamel delivered 3 units of tanks, proving the structural and chemical durability of our Water Tanks in the most demanding industrial applications.

Choosing a Beverage Wastewater Tank from Center Enamel is a strategic investment in the long-term sustainability of your facility.

The combination of Epoxy Coated Tanks and Aluminum Dome Roofs eliminates the need for expensive structural repairs and re-coating projects. The smooth internal surfaces simplify cleaning and maintenance, reducing the operational burden on the plant staff.

By providing secure containment for high-strength effluent, we help beverage producers prevent groundwater contamination and protect local aquatic ecosystems. Our systems facilitate the recovery of water and energy, supporting the industry's move toward a circular economy.

The Beverage Wastewater Tank is a critical asset in the modern production facility. Its ability to withstand chemical aggression, thermal stress, and biogenic corrosion directly impacts the facility's compliance and profitability.

As the leading China Beverage Wastewater Tank manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) remains at the forefront of the industry. By combining the resilience of Epoxy Coated Tanks with the innovation of Aluminum Dome Roofs, we provide the global market with the most advanced and reliable Water Tanks for wastewater treatment. With successful installations in more than 100 countries, our expertise ensures that your beverage wastewater project will be a sustainable success.