As the Global Marketing Promotion Writer for Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), I focus on the specialized engineering required for the most demanding segment of fuel storage: the Underground Oil Tank (UST). These tanks, commonly used for retail fueling stations, fleet fueling depots, and industrial facilities, are the unseen foundation of global logistics and energy distribution. Storing volatile and hazardous petroleum products beneath the earth demands a containment system built not just for longevity, but for verifiable, impenetrable environmental protection against the relentless corrosive forces of soil and groundwater.

We stand as a premier China Underground Oil Tanks Manufacturer, specializing in high-integrity, customized Welded Steel Tanks. Our expertise is concentrated on fabricating double-walled, jacketed containment vessels that excel in critical areas: absolute leak protection, superior external corrosion resistance, structural resilience against burial loads, and full compliance with the most stringent international standards (such as UL and related environmental agency guidelines). Our commitment to quality ensures that our tanks are assets of maximum safety, compliance, and long-term service life, safeguarding the environment and our clients' operations across diverse global markets.

The decision to place an oil tank underground is driven by a combination of practical, aesthetic, and safety-related factors, making the Underground Oil Tank a unique engineering challenge compared to its aboveground counterpart.

Superior Safety and Fire Mitigation: Burial naturally provides an unparalleled level of fire protection by isolating volatile fuels from surface hazards, heat sources, and potential ignition points. This inherent concealment also reduces the risk of vandalism or accidental damage.

Thermal Stability and Purity: The surrounding soil acts as a natural insulator, maintaining a remarkably stable temperature for the stored fuel. This thermal stability is essential for minimizing evaporation losses, controlling the fuel's density, and extending its life.

Space Optimization and Aesthetics: USTs allow for the complete utilization of valuable surface real estate—critical for high-traffic areas like retail fueling stations—and maintain the aesthetics of the site by keeping large storage vessels out of view.

However, the advantages of concealment introduce the monumental challenge of verifiable containment. A leak in an underground environment is difficult to detect quickly and remediation can be enormously costly, necessitating a storage vessel of absolute, unwavering integrity.

The definitive solution for this challenge is the Welded Steel Tank with specialized secondary containment and corrosion protection. Its monolithic, rigidly welded structure is essential for resisting the external pressures of burial while providing a robust, long-term primary barrier.

Shijiazhuang Zhengzhong Technology Co., Ltd, known globally as Center Enamel, leverages its deep expertise in precision steel fabrication, advanced welding technology, and environmental compliance to excel as a China Underground Oil Tanks Manufacturer. We deliver Welded Steel Tanks that are recognized as a global standard for safety and leak prevention.

The design and manufacture of an Underground Oil Tank must primarily focus on counteracting the corrosive forces of the earth and providing an integrated secondary containment barrier. Our expertise in specialized Welded Steel Tanks fabrication ensures every critical aspect is addressed, guaranteeing environmental compliance and structural longevity.

The greatest threat to an Underground Oil Tank's lifespan is the external corrosion caused by moisture, soil chemistry, and electrolysis.

Double-Wall Construction: Our Underground Oil Tanks are predominantly double-walled, featuring an inner Welded Steel primary containment vessel and a secondary containment layer. The gap, or interstitial space, is monitored for liquid or vapor to provide instantaneous electronic leak detection, meeting stringent environmental protection agency (EPA) requirements globally.

Fiberglass-Reinforced Plastic (FRP) Jacketing: The exterior of the Welded Steel primary tank is meticulously encased in a specialized, non-corrosive Fiberglass-Reinforced Plastic (FRP) jacket. This robust jacket effectively isolates the steel from the corrosive soil and groundwater environment, eliminating the need for complex cathodic protection systems and guaranteeing long-term containment integrity.

Corrosion-Resistant Steel: The internal Welded Steel Tank is constructed from certified, high-grade carbon steel, processed and joined using automated, high-quality welding procedures. The rigorous welding protocols ensure the monolithic shell maintains its integrity against internal pressure and external loads.

Unlike aboveground tanks, USTs must endure static and dynamic external loads from the earth, surrounding backfill, and surface traffic.

Horizontal Cylindrical Design: Underground Oil Tanks are typically manufactured in a horizontal cylindrical form with domed or flanged ends. This geometry is intrinsically strong, distributing the pressure of the surrounding earth evenly across the tank surface, preventing deformation.

Structural Reinforcement: Internal stiffeners and robust end caps are strategically welded into the structure to resist the compressive forces exerted by the soil and the hydrostatic uplift pressure from high water tables. This is especially critical in areas with heavy surface traffic or high water tables.

Compliance with UL: The Welded Steel Tank structure is manufactured in strict compliance with Underwriters Laboratories (UL) standards for steel USTs storing flammable and combustible liquids, verifying its structural ability to withstand burial conditions.

USTs require specialized monitoring and access components that are structurally integrated into the vessel itself, ensuring they function reliably over decades underground.

High-Integrity Ports and Access: All openings for fill, delivery, suction, and monitoring are structurally reinforced and permanently welded to the tank shell. These ports accommodate specialized fittings for Automatic Tank Gauging (ATG) systems, overfill prevention devices, and secondary containment monitoring probes. Manways are included for internal inspection and cleaning.

Overfill Prevention Systems: Tanks are equipped with overfill prevention devices (OPD) that automatically restrict the flow of fuel as the tank approaches its safe filling limit, preventing a catastrophic surface spill and complying with environmental safety mandates.

Continuous Interstitial Monitoring: The electronic monitoring of the space between the inner steel tank and the outer FRP jacket provides a continuous, highly sensitive defense against leaks, providing instantaneous alert of any breach in the primary containment vessel.

While the external environment is hostile, the internal environment must be optimized for fuel purity.

Internal Cleanliness and Coatings: Tanks are rigorously cleaned post-fabrication to remove all welding debris. For specialized fuels, internal coatings may be applied to the welded steel surface to prevent internal rust and scaling, preserving the quality of the refined fuel and protecting dispensing equipment.

Sloped Bottom for Water Management: Tanks are engineered with a slight internal slope leading to a low-point sump. This critical feature allows water (from condensation or delivery) and heavy sediment to consolidate, ensuring it does not enter the pumping system.

Our dedication to the specialized manufacturing of Welded Steel Underground Oil Tanks establishes us as a leader among China Underground Oil Tanks Manufacturers. We do not simply fabricate steel; we engineer Underground Oil Tanks for total regulatory compliance and minimum environmental risk.

Code-Driven Fabrication: We possess deep institutional knowledge of the most demanding environmental and safety codes globally. Our entire manufacturing workflow is structured to produce tanks that simplify the permitting and installation process for our clients.

Precision Welding and NDT: We utilize advanced, automated welding processes and rigorous Non-Destructive Testing (NDT) protocols specifically calibrated for heavy gauge steel. This ensures that the primary containment barrier is structurally monolithic and absolutely leak-proof before the tank is even jacketed.

Integrated Jacketing Expertise: Our proprietary process for bonding the protective FRP jacket to the welded steel shell is meticulously controlled and verified, guaranteeing a permanent, seamless isolation layer that defends against soil corrosion for the tank's entire design life.

Complete Documentation: We provide full documentation, including NDT records, material certificates, and compliance reports, which are essential for long-term asset management, insurance, and regulatory audits globally.

The following three non-fictitious projects showcase Center Enamel’s proficiency in delivering robust, high-integrity containment solutions across demanding industrial and environmental sectors, underscoring the manufacturing integrity and engineering precision applied to all our fabricated steel products, including Underground Oil Tanks.

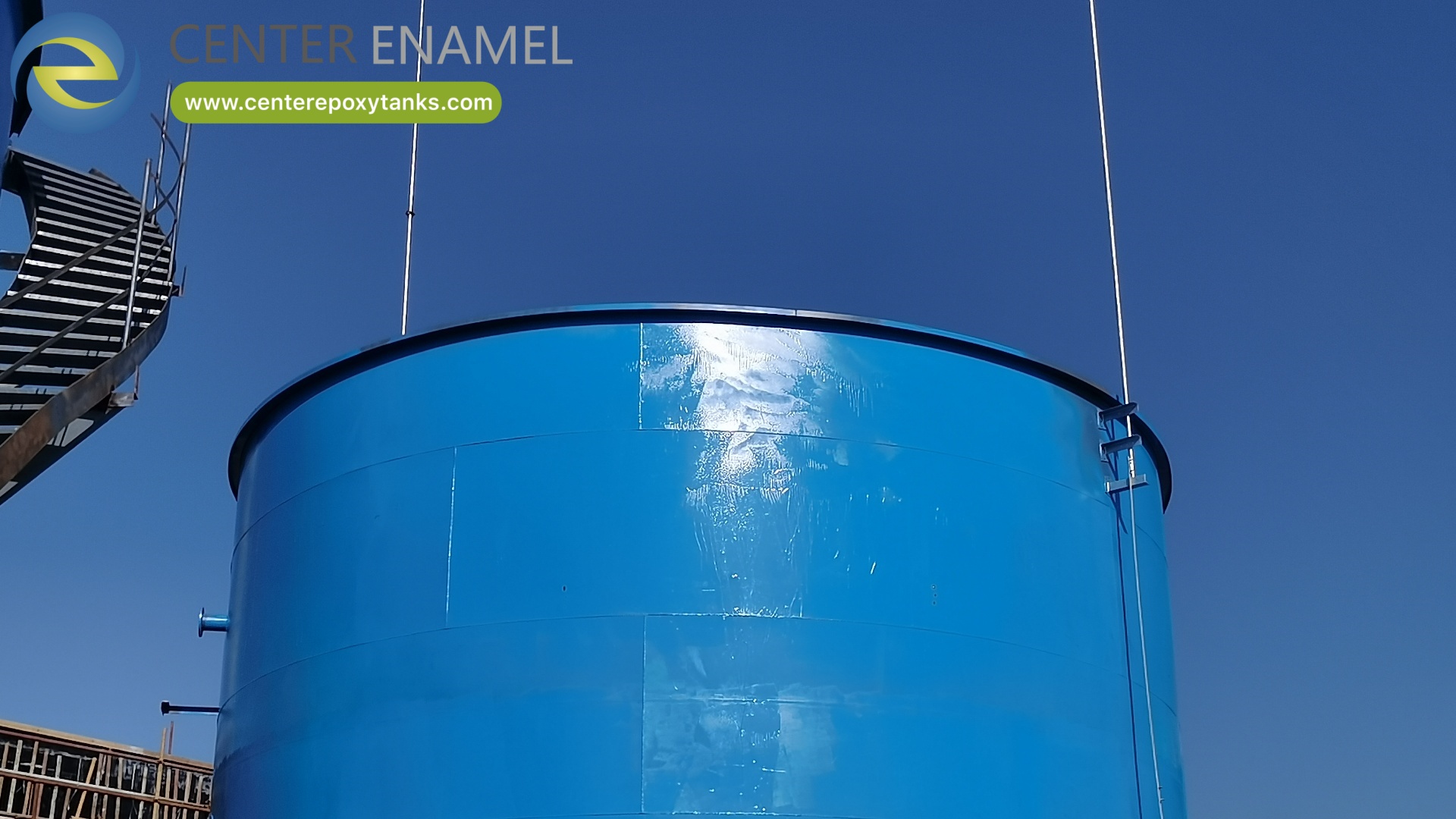

Ethiopia Textile Industrial Park Wastewater Treatment Project: This project involved the supply of 20 units with a massive combined capacity. This undertaking showcases our ability to manage the logistics and rigorous quality control required for high-volume, multi-unit projects that demand exacting standards for industrial liquid containment.

Hebei Cangzhou Industrial Wastewater Project: We delivered 12 units with a large total capacity for a major industrial wastewater project. This highlights our experience in supplying multiple, large-volume tanks to demanding industrial environments where chemical resistance, structural integrity, and long-term containment longevity are paramount.

Huadong Medicine Zhejiang Hangzhou Pharmaceutical Plant Wastewater Treatment Project: We delivered 6 units with a total capacity to a major pharmaceutical facility. This highlights our experience in manufacturing tanks for industries with strict regulatory and purity requirements, where the integrity of the storage vessel is critical to the entire process chain.

For fuel distributors, commercial developers, and industrial operators who require the most reliable, compliant, and structurally sound containment for their fueling infrastructure, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is the definitive China Underground Oil Tanks Manufacturer.

Our Welded Steel Tank solutions offer:

Absolute Environmental Protection: FRP jacketing and double-walled monitoring eliminate corrosion risk and provide verifiable leak detection.

Structural Reliability: Robust welded steel fabrication ensures the tank withstands earth pressure and provides decades of secure service.

Regulatory Compliance: Adherence to UL standards simplifies approval and guarantees a globally accepted safety asset.