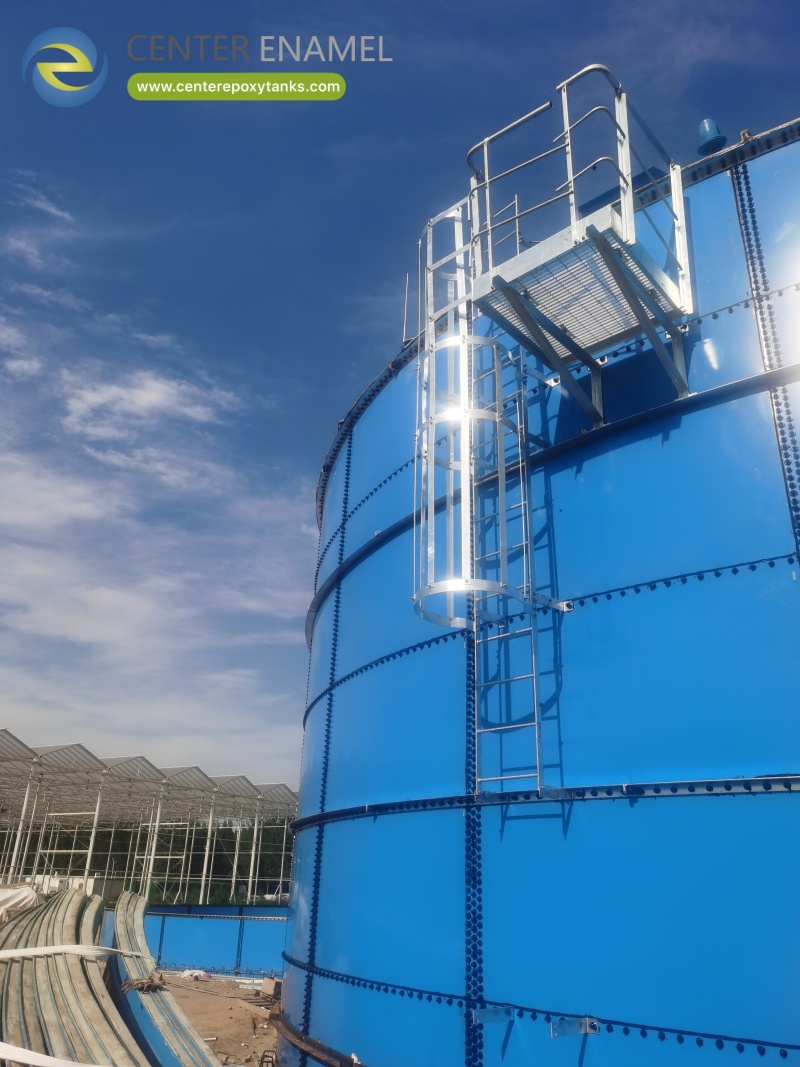

In the rapidly evolving field of biogas production, the efficiency of each component is critical to achieving optimal results. One of the most important aspects of any biogas facility is the storage system used to contain the raw materials and end products, such as biogas itself. For these applications, epoxy-coated tanks with smooth surfaces have proven to be an ideal choice. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) is a leading provider of these high-performance storage solutions, offering tanks that meet the rigorous demands of biogas production while ensuring longevity, reduced maintenance, and increased efficiency.

Epoxy-coated tanks are industrial storage tanks with a protective layer of epoxy resin applied to their internal and external surfaces. This coating enhances the durability and chemical resistance of the tanks, making them suitable for harsh industrial environments. The epoxy coating forms a seamless, non-porous surface that resists corrosion, wear, and the buildup of contaminants.

In biogas production, where materials such as organic waste undergo anaerobic digestion to generate biogas, the tank materials must be able to withstand chemical aggression from biogas byproducts, such as hydrogen sulfide, volatile organic compounds, and other corrosive substances. Epoxy-coated tanks are designed to handle these conditions, providing a smooth surface that minimizes the accumulation of waste and reduces maintenance requirements.

The use of epoxy-coated tanks offers many key advantages, making them particularly well-suited for biogas projects. These benefits include:

Superior Corrosion Resistance

Biogas production generates a variety of corrosive byproducts, including hydrogen sulfide, ammonia, and volatile organic compounds. Epoxy coatings form a strong protective barrier against these substances, preventing the tank structure from deteriorating. The chemical resistance of epoxy-coated tanks ensures they will maintain their structural integrity throughout the entire operational life of the biogas facility.

Smooth Surface to Minimize Sludge Build-Up

One of the most significant challenges in biogas systems is the buildup of sludge and organic residues in storage tanks. This accumulation can create operational inefficiencies, such as blocking pipes, reducing gas production, and increasing cleaning requirements. Epoxy-coated tanks provide a smooth, non-porous surface that significantly reduces the buildup of sludge, preventing the formation of biofilm and facilitating the efficient flow of material through the system.

Reduced Maintenance Requirements

Because epoxy-coated tanks resist corrosion and sludge build-up, they require far less maintenance compared to traditional tanks made from steel or concrete. The smooth interior surface allows for easy cleaning, reducing the need for frequent inspections and downtime. This makes epoxy-coated tanks a cost-effective solution for biogas operators looking to minimize operational disruptions and maintenance costs.

Enhanced Gas Tightness

In any biogas system, it is essential to maintain a sealed environment to prevent gas leaks, which could lead to safety hazards and energy losses. Epoxy-coated tanks offer excellent gas-tight sealing properties, which help maintain the integrity of the gas storage system. This is crucial in biogas applications, where maximizing gas retention is key to ensuring efficient energy recovery.

Long-Term Durability

Epoxy-coated tanks are designed to withstand extreme conditions, including exposure to harsh chemicals, fluctuating temperatures, and mechanical stress. This makes them ideal for biogas applications, where tanks are exposed to volatile substances and are in constant use. The longevity of epoxy-coated tanks translates to lower replacement costs and fewer operational disruptions.

Epoxy-coated tanks are used in various stages of biogas production, storage, and utilization. Their versatile design makes them suitable for a wide range of applications, including:

Anaerobic Digesters

Anaerobic digesters are the primary units where organic waste is broken down to produce biogas. Epoxy-coated tanks are an excellent choice for these digesters due to their chemical resistance and smooth surfaces. These tanks ensure optimal digestion conditions and minimize the risk of contamination from the digestate.

Biogas Storage Tanks

Once biogas has been produced, it needs to be stored before being converted into energy. Epoxy-coated tanks provide a gas-tight environment for storing biogas, helping to reduce methane loss and ensure a continuous, reliable gas supply. The durability and reliability of these tanks make them perfect for long-term biogas storage.

Substrate Storage Tanks

Biogas production requires a continuous supply of organic material, such as food waste, agricultural residues, and manure. Epoxy-coated tanks are ideal for storing these substrates before they are fed into the digester. These tanks are resistant to the corrosive nature of organic acids and fermentation byproducts, ensuring that the quality of the substrate remains high.

Digestate Storage Tanks

The byproduct of anaerobic digestion, known as digestate, can be stored and used as a nutrient-rich fertilizer. Epoxy-coated tanks provide the necessary storage conditions for digestate, preventing nutrient loss and ensuring that the digestate is stored in a safe, environmentally-friendly manner.

Shijiazhuang Zhengzhong Technology Co., Ltd. is a leader in providing high-quality storage solutions for biogas engineering, including epoxy-coated tanks. The company has over 30 years of experience in the industry and specializes in offering customized solutions that meet the unique needs of biogas operators.

Industry Expertise

With decades of experience in storage solutions for various industries, Shijiazhuang Zhengzhong Technology Co., Ltd. understands the complexities of biogas production and storage. The company works closely with clients to design and manufacture tanks that meet the specific needs of each biogas facility, ensuring optimal performance and efficiency.

Advanced Manufacturing Technologies

Shijiazhuang Zhengzhong Technology Co., Ltd. uses state-of-the-art manufacturing technologies to produce epoxy-coated tanks. The company utilizes advanced coating techniques to ensure that each tank has a durable, high-quality epoxy finish that can withstand the harsh conditions of biogas production.

Customization and Flexibility

Each biogas project has its own unique requirements in terms of capacity, operating conditions, and environmental factors. Shijiazhuang Zhengzhong Technology Co., Ltd. offers fully customized epoxy-coated tanks, ensuring that each tank is designed to meet the specific needs of the project. This includes custom sizes, tank configurations, and materials that optimize the performance of the biogas system.

Comprehensive Support and After-Sales Services

Shijiazhuang Zhengzhong Technology Co., Ltd. offers end-to-end solutions for biogas storage, from design and manufacturing to installation and ongoing maintenance support. The company’s experienced team provides expert consultation and technical assistance, ensuring that biogas operators get the most out of their storage solutions.

Epoxy-coated tanks with smooth surfaces are a game-changer for the biogas industry, offering superior durability, enhanced gas-tightness, and reduced maintenance requirements. Shijiazhuang Zhengzhong Technology Co., Ltd. has positioned itself as a leading provider of these advanced storage solutions, helping biogas operators worldwide achieve higher efficiency, lower operational costs, and improved sustainability in their operations.