Hydraulic oil is the lifeblood of a hydraulic system, transferring power and lubricating critical components. The reservoir, or Welded Steel Hydraulic Oil Tank, plays four essential roles that go far beyond simple storage:

Heat Dissipation: It must possess sufficient surface area to cool the oil, which generates significant heat under pressure.

Contaminant Separation: It allows time for air, foam, and solid contaminants to separate from the fluid before recirculation.

Volume Buffering: It holds reserve volume to compensate for fluid displacement in cylinders and thermal expansion.

Structural Support: It often serves as the mounting platform for pumps, filters, and other hydraulic components.

A failure in the design or integrity of a hydraulic oil tank can lead directly to system overheating, cavitation, premature component wear, and complete operational failure. The storage environment for the fluid is as critical as the fluid itself.

Welded Steel Hydraulic Oil Tanks demand a design that is robust, versatile, and highly focused on functional performance, requiring exceptional attention to:

Internal Baffling and Geometry: Meticulous design of internal structures to control fluid flow, maximize retention time, and facilitate the separation of contaminants.

Structural Rigidity: The tank must be strong enough to withstand vibration, external loads, and the mounting stress from heavy pumps and motors.

Cleanliness and Coating: The internal surfaces must be perfectly clean and often coated with specialized, compatible linings to prevent rust, scaling, and particulate contamination of the highly sensitive hydraulic fluid.

The established, definitive solution for durable, high-performance fluid conditioning is the custom-engineered Welded Steel Tank. Its fabrication versatility allows for the precise integration of internal baffles, robust mounting plates, and specialized access points essential for hydraulic service.

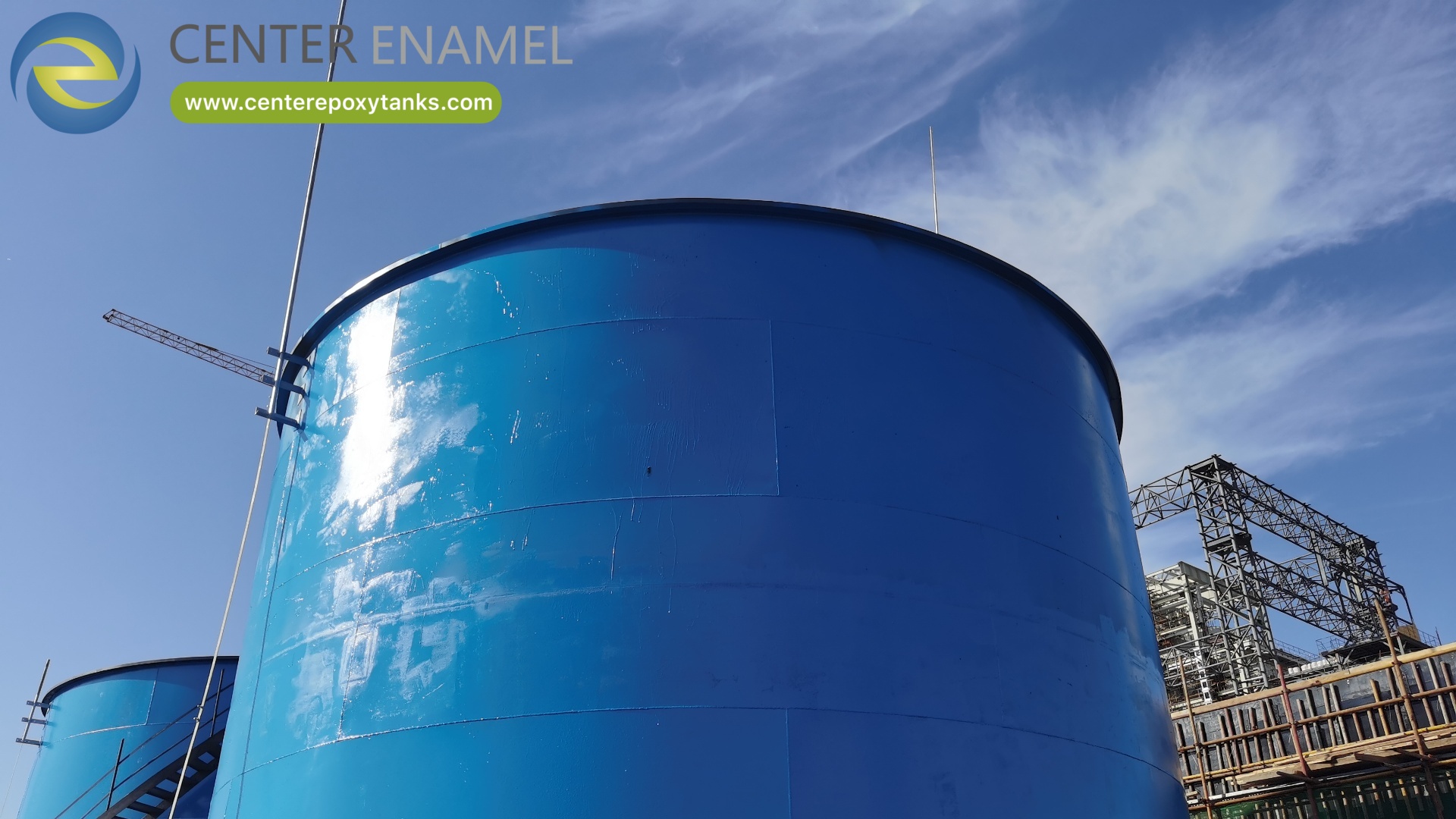

Shijiazhuang Zhengzhong Technology Co., Ltd, known globally as Center Enamel, leverages its deep expertise in precision steel fabrication and quality management to excel as a China Welded Steel Hydraulic Oil Tanks Manufacturer. We deliver custom-engineered Welded Steel Tanks that strictly adhere to relevant industry specifications, ensuring our clients receive reservoirs engineered for maximum efficiency, structural integrity, and unparalleled operational lifespan.

The complexity of a hydraulic reservoir lies not in its function as a container, but in its function as a fluid conditioner. Our expertise in specialized Welded Steel Tanks fabrication ensures every critical aspect is addressed, guaranteeing the reliability of the entire hydraulic system.

The internal design of the tank is crucial for separating contaminants and conditioning the fluid before it returns to the pump.

Baffle Plates: We incorporate internal baffle plates, strategically placed and meticulously welded in position. The baffle's primary function is to physically separate the fluid returning from the system (the 'return line') from the fluid being drawn by the pump (the 'suction line'). This separation maximizes the fluid's retention time, allowing air bubbles to rise and solid particles to settle to the bottom.

Optimal Fluid Velocity: The baffle design also controls the flow path within the tank, slowing down the fluid velocity to optimize the settling and cooling process. This ensures the fluid is stable, clean, and cool when the pump draws it back into the active circuit.

Return Line Submergence: The return line is designed to discharge below the oil level to prevent aeration and foaming, which can lead to pump cavitation and system damage.

A Welded Steel Hydraulic Oil Tank often bears the weight and vibration of the power unit, demanding superior structural design.

Heavy-Duty Steel Construction: We utilize high-grade carbon steel, precisely cut and joined using automated welding procedures. The structural integrity is paramount, allowing the tank to withstand high frequency vibration and substantial static loads from externally mounted pumps, motors, and manifold blocks.

Base Plate and Mounting Rigidity: The tank includes structural reinforcement, particularly at the mounting points for the power unit. This rigidity prevents drumming, reduces transmitted vibration, and ensures the critical alignment of pump and motor remains stable over time.

Vibration Dampening: In high-stress applications, the tank base design can incorporate features for vibration isolation, further extending the life of both the tank and the mounted components.

The purity of the hydraulic oil is non-negotiable, requiring specialized attention to the tank's interior and access points.

Internal Cleanliness: Immediately following fabrication, all internal surfaces of the Welded Steel Tank are subjected to rigorous cleaning procedures, including shot blasting and specialized washing, to remove all welding spatter, scale, and contaminants. This factory cleanliness is vital for starting the system with high-purity fluid.

Protective Linings: Depending on the client's specification and the operating environment, the tank interior may be coated with specialized, oil-compatible, non-reactive linings. These coatings prevent rust formation, which is a major source of particulate contamination.

Access for Maintenance: Tanks are equipped with strategically placed access covers and clean-out ports. These are sized and positioned to allow maintenance personnel to safely access the tank bottom to remove settled sludge and contaminants, facilitating preventative maintenance and extending fluid life.

The tank must facilitate easy monitoring and safe, efficient operation of the hydraulic system.

Level and Temperature Gauges: Tanks include robust fittings for oil level indicators (sight glasses) and temperature gauges, allowing operators to quickly verify the two most critical operational parameters.

Breather and Filtration Interfaces: Dedicated ports are designed for high-efficiency breathers (air filters) and return line filters. The breather is vital for preventing airborne moisture and dust from entering the system, while the filter connections ensure rapid fluid conditioning.

Drain and Fill Ports: Secure, well-positioned drain ports are integrated at the lowest point to allow for complete, clean fluid changes. Similarly, dedicated fill ports with integrated strainers prevent large particles from entering during replenishment.

Our position as a specialized China Welded Steel Hydraulic Oil Tanks Manufacturer is built on a foundation of precision engineering, advanced fabrication technology, and a commitment to stringent industrial quality standards in the creation of Welded Steel Tanks.

Precision Welding for Integrity: We utilize advanced, controlled welding procedures, ensuring every internal baffle, mounting plate, and exterior seam is structurally sound and leak-proof. The quality of our welds ensures the tank's integrity under constant vibration and pressure.

Customization and Design Flexibility: Our engineering team works closely with equipment manufacturers to customize tank dimensions, baffle configurations, and port placements to perfectly match the hydraulic system's flow rate, heat load, and space constraints, maximizing cooling efficiency and conditioning time.

Quality Assurance and Inspection: Our Quality Assurance and Quality Control (QA/QC) programs involve meticulous dimensional checks, weld integrity testing, and stringent final cleanliness verification before shipment. This ensures the tank is delivered ready for installation and immediate high-performance service.

Integrated Solutions: Our ability to supply custom-engineered, application-specific tanks provides equipment manufacturers with a reliable, performance-driven component that directly enhances the reputation and durability of their final product.

The following three projects showcase Center Enamel’s proficiency in delivering robust, high-integrity containment solutions across demanding industrial and environmental sectors, underscoring the manufacturing integrity applied to all our fabricated steel products, including Welded Steel Hydraulic Oil Tanks.

Ethiopia Textile Industrial Park Wastewater Treatment Project: This project involved the supply of 20 units with a massive combined capacity, showcasing our ability to manage the logistics and quality control for high-volume, multi-unit projects that require exacting standards for industrial liquid containment.

Hebei Cangzhou Industrial Wastewater Project: We delivered 12 units with a large total capacity for a major industrial wastewater project, highlighting our experience in supplying multiple, large-volume tanks to demanding industrial environments where chemical resistance and structural longevity are paramount.

Huadong Medicine Zhejiang Hangzhou Pharmaceutical Plant Wastewater Treatment Project: We delivered 6 units with a total capacity to a major pharmaceutical facility. This highlights our experience in manufacturing tanks for industries with strict regulatory and purity requirements, where the integrity of the storage vessel is critical to the entire process.

For hydraulic power unit manufacturers, heavy equipment builders, and industrial maintenance engineers who demand precision, durability, and verifiable fluid conditioning performance, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is the definitive China Welded Steel Hydraulic Oil Tanks Manufacturer.

Our Welded Steel Tank solutions offer:

Enhanced Fluid Conditioning: Precisely engineered internal baffles maximize air separation, cooling, and contamination settling time.

Structural Durability: Heavy-duty, precision welding ensures the tank withstands constant vibration and heavy static loads, extending system life.

Oil Purity: Superior internal cleanliness and protective coatings minimize internal contamination, protecting sensitive pumps and valves.

We invite you to partner with Center Enamel to secure your critical hydraulic infrastructure with Welded Steel Hydraulic Oil Tanks built to the highest global standards for quality, resilience, and operational excellence.